| Availability: | |

|---|---|

| Quantity: | |

Features:

High Productivity

High degree of automation

Blanking and other model production can be applied

Double trolley automatically switch stacks

Regular shaped and irregular shaped sheet stacks

High security

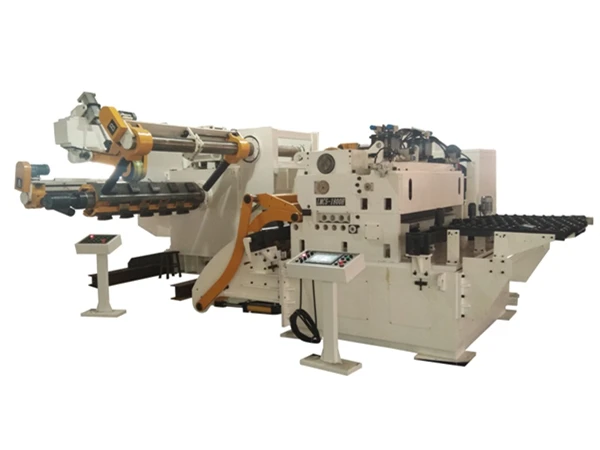

Composition:

Coil loading car→Decoiling structure→Feeding structure→Straightening structure→Fixed length feeding structure→Material head shearing structure→Oil coating device→Tail material feeding device→Fully automatic telescopic belt conveyor→Automatic double station stacker.

Specification:

Model | LMC6-1000 | LMC6-1300 | LMC6-1600 | LMC6-1800 |

Coil width | 100-1000mm | 100-1300mm | 200-1600mm | 200-1800mm |

Coil thickness | 0.6-6.0mm | 0.6-6.0mm | 0.6-6.0mm | 0.6-6.0mm |

Coil load | 8000kg | 10000kg | 15000kg | 28000kg |

Coil inside diameter | 580-610mm | 580-610mm | 580-610mm | 580-610mm |

Coil outside diameter | 1400mm | 1400mm | 1400mm | 1400mm |

Feeding speed | 24m/min | 24m/min | 24m/min | 24m/min |

Straightening Roller | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 |

Belt width | 1000mm | 1300mm | 1600mm | 1800mm |

Convey speed | 0-60m/min | 0-60m/min | 0-60m/min | 0-60m/min |

Max volume | 1000*1000mm | 1300*1300mm | 1600*1600mm | 1800*1600 |

Min volume | 300*300mm | 300*300mm | 300*300mm | 300*300mm |

Stacking height | 500mm | 500mm | 500mm | 500mm |

Stacking weight | 3000kg | 5000kg | 5000kg | 7000kg |

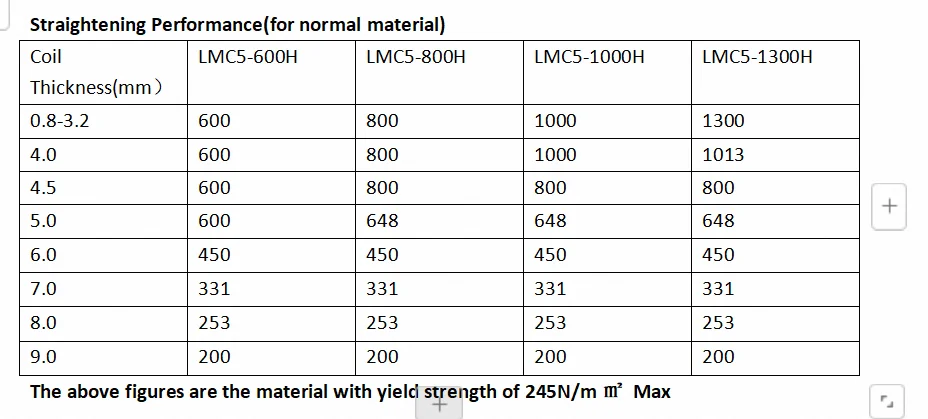

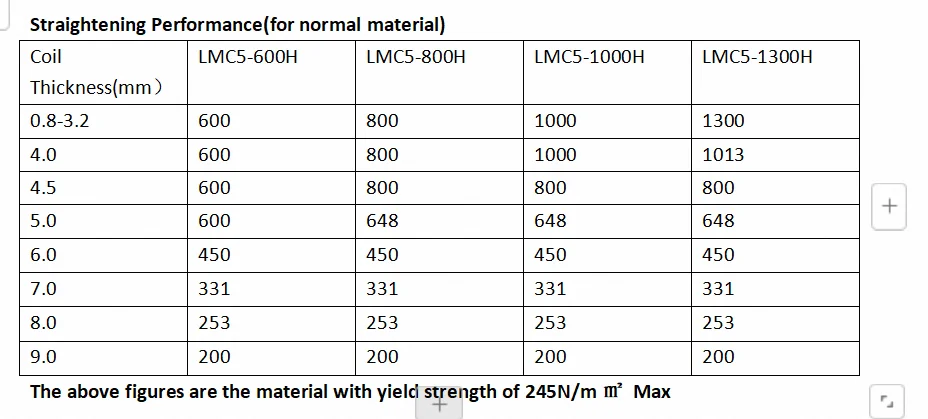

| Item/Model | LMC5-600H | LMC5-800H | LMC5-1000H | LMC5-1300H |

| Coil Width(mm) | 70-600 | 70-800 | 70-1000 | 70-1300 |

| Coil Thickness(mm) | 0.8-9.0 | 0.8-9.0 | 0.8-9.0 | 0.8-9.0 |

| Coil Inside Diameter (mm) | 508 | 508 | 508 | 508 |

| Coil Outside Diameter (mm) | 1400 | 1400 | 1400 | 1400 |

| Coil Load(kg) | 5000 | 5000 | 7000 | 8000 |

| Feeding Speed | 16m/min | 16m/min | 16m/min | 16m/min |

| Straightening Roller | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 |

| Feeding Roller | Upper1 Lower1 | Upper1 Lower1 | Upper1 Lower1 | Upper1 Lower1 |

| Main Motor | AC7.5KW | AC7.5KW | AC11.0KW | AC15KW |

| Decoil Expansion | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Decoil Motor | 3.7KW | 3.7KW | 5.5KW | 5.5KW |

Features:

High Productivity

High degree of automation

Blanking and other model production can be applied

Double trolley automatically switch stacks

Regular shaped and irregular shaped sheet stacks

High security

Composition:

Coil loading car→Decoiling structure→Feeding structure→Straightening structure→Fixed length feeding structure→Material head shearing structure→Oil coating device→Tail material feeding device→Fully automatic telescopic belt conveyor→Automatic double station stacker.

Specification:

Model | LMC6-1000 | LMC6-1300 | LMC6-1600 | LMC6-1800 |

Coil width | 100-1000mm | 100-1300mm | 200-1600mm | 200-1800mm |

Coil thickness | 0.6-6.0mm | 0.6-6.0mm | 0.6-6.0mm | 0.6-6.0mm |

Coil load | 8000kg | 10000kg | 15000kg | 28000kg |

Coil inside diameter | 580-610mm | 580-610mm | 580-610mm | 580-610mm |

Coil outside diameter | 1400mm | 1400mm | 1400mm | 1400mm |

Feeding speed | 24m/min | 24m/min | 24m/min | 24m/min |

Straightening Roller | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 |

Belt width | 1000mm | 1300mm | 1600mm | 1800mm |

Convey speed | 0-60m/min | 0-60m/min | 0-60m/min | 0-60m/min |

Max volume | 1000*1000mm | 1300*1300mm | 1600*1600mm | 1800*1600 |

Min volume | 300*300mm | 300*300mm | 300*300mm | 300*300mm |

Stacking height | 500mm | 500mm | 500mm | 500mm |

Stacking weight | 3000kg | 5000kg | 5000kg | 7000kg |

| Item/Model | LMC5-600H | LMC5-800H | LMC5-1000H | LMC5-1300H |

| Coil Width(mm) | 70-600 | 70-800 | 70-1000 | 70-1300 |

| Coil Thickness(mm) | 0.8-9.0 | 0.8-9.0 | 0.8-9.0 | 0.8-9.0 |

| Coil Inside Diameter (mm) | 508 | 508 | 508 | 508 |

| Coil Outside Diameter (mm) | 1400 | 1400 | 1400 | 1400 |

| Coil Load(kg) | 5000 | 5000 | 7000 | 8000 |

| Feeding Speed | 16m/min | 16m/min | 16m/min | 16m/min |

| Straightening Roller | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 | Upper5 Lower4 |

| Feeding Roller | Upper1 Lower1 | Upper1 Lower1 | Upper1 Lower1 | Upper1 Lower1 |

| Main Motor | AC7.5KW | AC7.5KW | AC11.0KW | AC15KW |

| Decoil Expansion | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Decoil Motor | 3.7KW | 3.7KW | 5.5KW | 5.5KW |